Embalaje de San Te

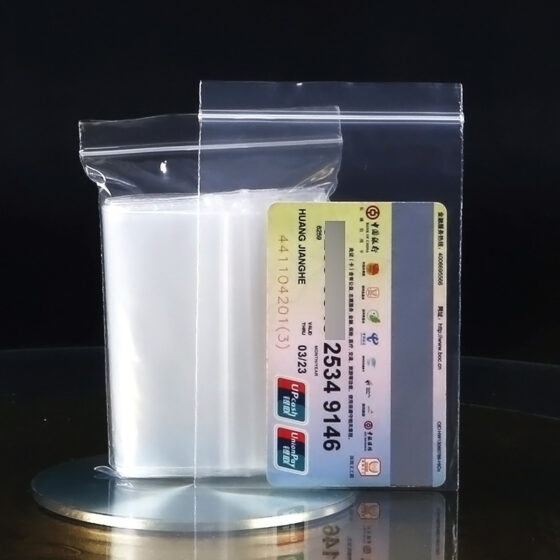

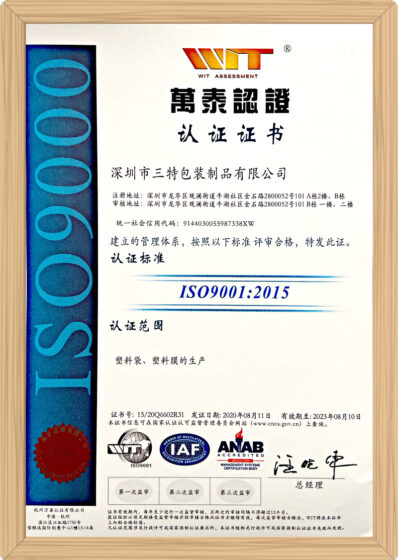

Sante Packaging es un proveedor líder de soluciones integrales para el embalaje de bolsas de plástico a gran escala en la industria, serving dozens of Fortune 500 clients and hundreds of high-end brands. Proporcionamos un diseño profesional de empaques de bolsas de plástico, research and development, production, and sales services for high-end electronics, express e-commerce, daily necessities, cosmetics, and other industries. The company was established in 2010, con bases de producción ubicadas en seis bases de producción en la región del delta del río Perla, incluyendo Shenzhen, Dongguan, Huizhou, y Zhongshan. El área de producción actual ha terminado 100000 square meters, con un equipo de producción de más de 420 gente, Un equipo de investigación y desarrollo de 8 gente, y más de 30 Personal de gestión. Tenemos 6 Máquinas avanzadas de película de fundición, 32 Máquinas de película soplada, más que 100 Máquinas de corte y fabricación de bolsas, y más de 30 Máquinas de impresión multicolor en la industria. Main production: CPE zipper bags, PE zipper bags, PE bone bags, round bottom bags, CPE self-adhesive bags, CPE frosted bags, PE plastic bags, PE/PO bags, fully biodegradable bags, PE flat bags, PE self sealing bags, PET/POF heat shrink bags, OPP/CPP composite bags, pearl cotton EPE, express waterproof bags, PE stretch film, cling film, bubble bags, die-cutting series and other packaging products. All products undergo multiple inspection procedures, including incoming inspection, production inspection, incoming inspection, and outgoing inspection, to ensure that the quality of all outgoing products is qualified and fully meets the customer's production standards.

Nuestros clientes provienen de todo el mundo

intelligent design

Intelligent design capability, intelligent structural design, intelligent image cutout, intelligent layout, etc., generated online

Sample production

We also provide structural replication, modification, and design services to meet the specific needs of our clients.

Process onlineization

Process and online implementation of requirements for order acceptance, delivery, evaluation, and sample production

Supply capacity

Ability to achieve fast scheduling production, inspection and shipment, and global 72 hour shipment

-

Los materiales y la composición de las bolsas de plástico PE.

¿Cuál es el nombre de la materia prima principal de las bolsas de plástico PE?? Its full name ... -

Aplicación de bolsas esmeriladas CPE en la fabricación de bolsas de ropa

¿Cómo se produce la bolsa esmerilada CPE?, también conocida como bolsa de plástico CPE, es ... -

Ventajas y preferencias del mercado de las bolsas autoadhesivas CPE

La bolsa autoadhesiva CPE es un tipo de bolsa esmerilada CPE, which belongs to the film plastic ... -

¿Qué bolsas de plástico podemos hacer para Shenzhen Sante Packaging?

Shenzhen Sante Packaging Products Co., Ltd. se encuentra en la calle Guanlan, Distrito de Longhua, Shenzhen. Our company ...

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.